Actua in Conversation with Jayson Myers CEO of NGen

How NGen’s Careers of the Future Campaign is Addressing Canada’s Skilled Labour Shortage

July 7, 2022

Jennifer Flanagan, Founder and CEO of Actua, sat down with Jayson Myers, an award-winning business economist specializing in industrial and technological change and CEO of Next Generation Manufacturing Canada (NGen) – a not-for-profit organization leading Canada’s Advanced Manufacturing Supercluster in building world-class manufacturing capabilities.

What’s a Supercluster? Superclusters are areas of concentrated and intense business activity made up of companies, academic institutions and not-for-profit organizations that boost innovation and growth in a particular industry. Canada’s Innovation Superclusters Initiative has five industry-led consortiums: advanced manufacturing, ocean sciences, artificial intelligence, protein industry and digital technology. Check out how Actua supports these superclusters here.

Together they discussed how NGen and its Careers of the Future campaign are addressing our skilled labour shortage by spotlighting the different career opportunities available to youth in advanced manufacturing. They also discussed how STEM and traditional manufacturing collide to develop advanced manufacturing capabilities.

Watch or listen to their conversation and see our list of key takeaways below:

Actua in Conversation with Jayson Myers CEO of NGen

How NGen’s Careers of the Future Campaign is Addressing Canada’s Skilled Labour Shortage

Audio File

Key Takeaways

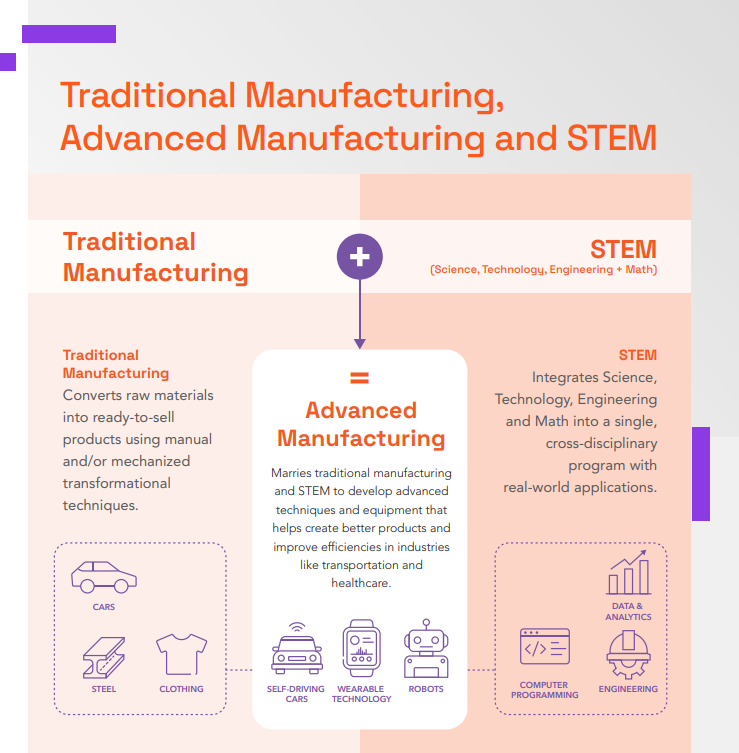

Advanced manufacturing is the use of technology within the manufacturing process.

Advanced manufacturing uses innovative and advanced technologies, such as robotics, artificial intelligence (AI) and 3D printing to create existing or new products. It is a manufacturing process that is highly adaptable, data-enabled and cost-efficient.

Advanced manufacturing is addressing some of the world’s biggest challenges.

NGen is an organization that invests in projects that are addressing global challenges such as climate change, food insecurity and life-threatening diseases. For example, they’re currently supporting the construction of a large facility in Southern Ontario that will be entirely automated to produce new forms of high-quality protein from crickets for things like pet food! This facility will use advanced equipment and machinery and could be replicated worldwide to address global food security.

NGen also has a new project underway to replace concrete construction blocks with more environmentally friendly ones. Concrete blocks are one of the biggest emitters of carbon dioxide worldwide. The new blocks take the waste from steel mills and inject carbon dioxide into them to create better and cheaper blocks. Not only is it a net-zero building material but a net negative as it’s taking carbon dioxide out of the air. Now, that’s cool!

STEM skills are fundamental to advanced manufacturing and careers of the future

STEM skills are fundamental to advanced manufacturing and careers of the future, but the skills needed to succeed in advanced manufacturing go well beyond technical skills and scientific knowledge. While skills like mathematics are logical, STEM is an applied, project-based approach to solving problems where different hypotheses are tested and explored. This approach, or way of thinking, is a crucial skill among advanced manufacturers. For example, some of the most commonly-used smart products on the market today are manufactured using advanced technologies. To achieve the customization and personalization these products are known for, advanced manufacturers must have a sound scientific understanding of the various materials used in product development.

There are tremendous opportunities for youth in advanced manufacturing.

With the rise of digitalization and advanced technology, manufacturing has become an extremely desirable field to work in, particularly for young people who want to make a difference. Electric vehicles are a perfect example of an innovative, or smart, product produced by advanced manufacturers. Yet, there is a shortage in the number of workers available to create electric vehicles. To continue growing and innovating, we need to become more automated and adopt more technology, but we also need people with digital and STEM skills to maintain and develop these technologies.

“That's why we must entice young people to look at this industry, not as it is today, but where it's going in the future, to develop the skills needed to push this industry forward.” - Jayson Myers, CEO, NGen

Advanced manufacturing requires a broad systems perspective.

Advanced manufacturing is trying to solve problems in systematic ways. Thus, problem-solving is critical, in addition to working collaboratively in teams and seeing the big picture. That’s because future careers will require a broader understanding of all systems in place – whether through business or social systems – and an understanding of how companies, academic institutions, not-for-profits, and the government can work together to develop innovative solutions for the future.

Diversity is key to advanced manufacturing.

Advanced manufacturing will only be successful if it can solve problems for the broad society. Narrow views about how to solve a problem are no longer working today. We need to understand the different issues facing diverse groups and be able to integrate diverse perspectives into the solutions we create so they serve the greatest number of people. Again, this requires a broad systems perspective.

For more information about NGen and its Careers of the Future campaign, visit CareersOfTheFuture.ca